As demand for the metal soars, the country is pursuing policies that will spur more smelters to run on clean electricity.

Good News

Elevance Health is integrating environmental sustainability, supply chain standards and AI-driven digital tools to transform healthcare delivery and improve patient outcomes. With a net zero target and a focus on climate resilience, the company is positioning environmental action as central to public health.

Arborists and land managers are trying “assisted migration” as global warming threatens livability in communities and the health of urban and rural forests.

As wildfires and extreme weather intensify, a coalition led by the Chicago Botanic Garden is working to shore up the Midwest’s dwindling supply of native seeds.

A new experiment shows biochar survives cow digestion largely intact, potentially turning cattle into a vehicle for spreading this carbon-stabilizing ingredient into the soil.

In more than half of U.S. states, Republican and Democratic lawmakers have introduced legislation that would boost adoption of DIY solar systems.

Researchers have developed a carbon-negative method for hydrogenation that uses bacteria fed on waste bread to generate hydrogen for chemical reactions.

The DIY solar hack arriving in US homes

26 February

Americans are embracing easy, plug‑and‑play solar units that slash energy costs — even as Washington tries to slow the clean‑energy shift.

Madison is proving electric buses can run through cold winters, providing a blueprint for zero-emissions transit in other frigid locales.

Legislation in Maine, Vermont, New Hampshire, Massachusetts and Rhode Island would allow small solar panels to plug directly into home outlets, expanding access to clean energy.

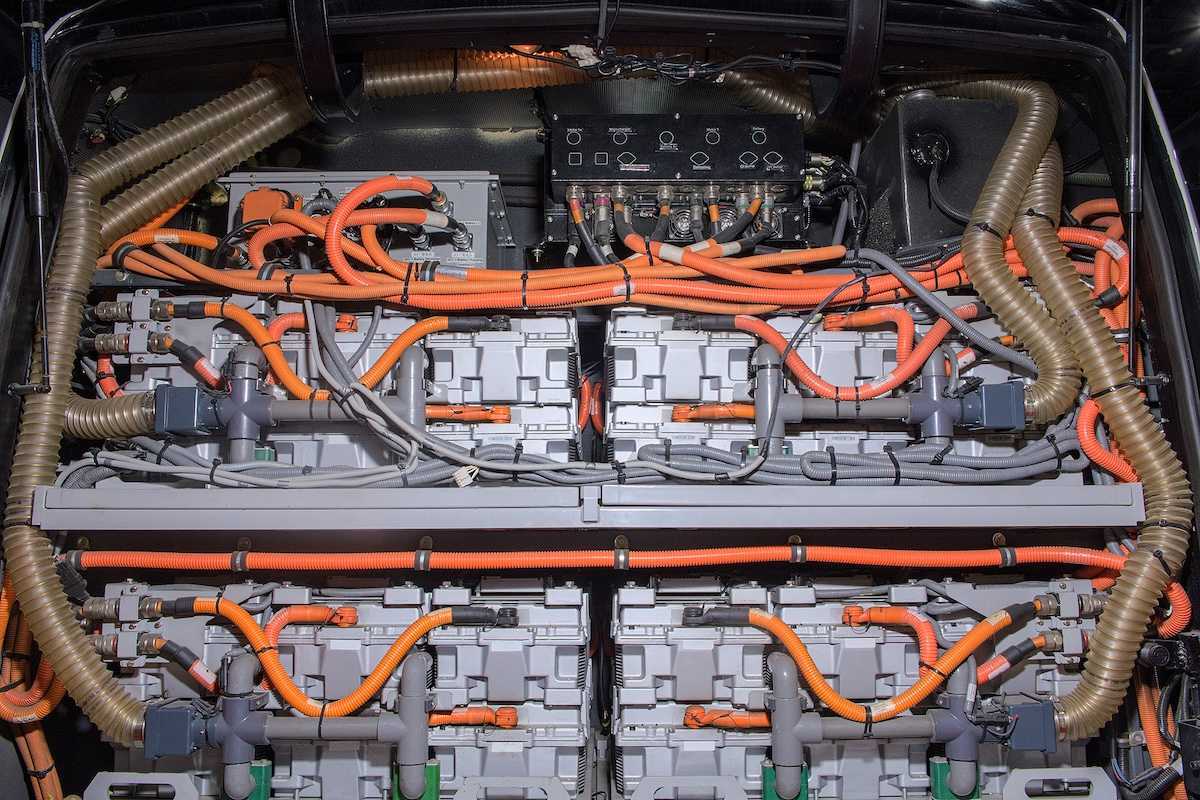

After reaching the end of their automotive careers, the batteries have been repurposed and are online in Texas.

Singapore is piloting the world’s first sustainable aviation fuel levy. It will slightly raise prices for airline passengers and cargo carriers flying to and from the city-state of 6 million people, home to Southeast Asia’s busiest airport.

Yet again, heat pumps were the most-shipped heating appliance in the U.S. And experts say the factors behind last year’s sales slide are temporary.

Falling emissions from the world’s biggest greenhouse gas emitter could mean a global turning point.

America’s two utility-scale offshore wind farms performed as well as gas power plants and better than coal in January — including during Winter Storm Fern.

Twenty-nine global banks reject financing a Papua New Guinea LNG project led by TotalEnergies, citing climate, environmental and human rights concerns.

In the wetlands of coastal southeast Louisiana, conservation groups are wrapping up a four-year project to plant 30,000 trees.

Advances in drilling and subsurface engineering are unlocking a constant, carbon-free power source deep within the Earth.

Journalism that drives the discussion

Copyright © 2017 Environmental Health Sciences. All rights reserved.

Copyright © 2017 Environmental Health Sciences. All rights reserved.